The world around us is changing at an incredible speed: technologies are developing, new scientific discoveries are emerging, manufacturers are coming to the conclusion that the environmental friendliness of production, the search for alternative sources of energy is not just a "chip", a fashion trend or a principled position of the owner, but a necessary condition for preservation planet for future generations.

The world community is switching to alternative energy sources: the future has already arrived! What about Ukraine?

Leading global manufacturers of industrial products are trying to make full use of the energy of the sun, wind and water, biogas and secondary energy resources, waves and tides, gas from organic waste and sewage treatment plants, etc. - all for the rational use of resources and preservation of the environment.

Leading scientists are also working on using secondary energy resources as efficiently as possible - blast furnace and coke gases, methane from coal deposits, waste energy potential of technological processes, etc.

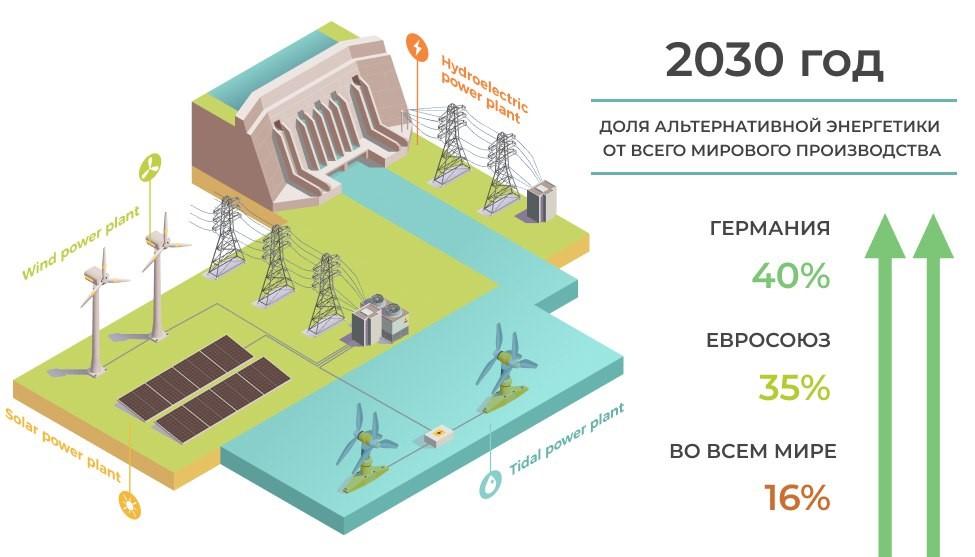

The International Energy Agency predicts that the share of alternative energy will be about 16% of the total world production by 2030, the European Union of Renewable Energy Sources calls an even higher figure - up to 35%. Leading experts claim: the future of mankind lies in alternative sources of energy!

In Germany, one of the leading countries in the use of alternative energy sources, the share of renewable energy may be 40%, and in the production of electricity - about 67%, the Federal Union of Renewable Sources predicts.

Last year, a scientific research laboratory for the search and use of alternative energy sources was also established on the basis of the "Perechyn Forest Chemical Plant".

Cooperation of "Perechyn Forest Chemical Plant" with "Technological Institute of Karlsruhe"

In December 2019, a scientific research laboratory started working on the basis of the plant, where PLHC specialists, together with employees of the well-known in Europe "Karlsruhe University of Technology" (Germany), are working on extremely important tasks, in particular:

the technology of obtaining additional energy from charcoal production waste. It is planned to direct it not only to the needs of production, but also to the creation of new products;

the technology of obtaining useful chemical compounds from wood in a natural way. It is mainly about the extraction of such compounds from pyrolysis gases. And this is a leading global trend!

The company is sincerely proud of the fact that it contributes to the protection of the environment together with the oldest technological university in Germany - an absolute authority in the matter of environmental protection of production.

"Perechyn Forest Chemical Plant" keeps up with the times: recognition of customers and environmental specialists

Adherence to the highest quality standards and ecological principles of production has made the Perechyn forest chemical plant a reliable partner of large foreign enterprises - the largest activated carbon plants in Europe, world leaders in silicon production.

Products can also be found in the largest European retail chains. The plant works according to BSCI, PEFC, ISO standards. In Ukraine, the plant's products are sold under the "GRILLY" TM, which confidently occupies the premium segment and is the choice of consumers focused on eco-friendly products. Its use is a sign of a conscious attitude towards oneself, one's surroundings and the environment. After all, quality coal is not a matter of price, it is a matter of health and personal safety.

Modern methods of industrial production of coal at the "Perechyn Forest Chemical Plant":

when environmental friendliness is an axiom!

In the production of charcoal, TDV "Perechynsky Forest Chemical Plant" uses only fuel wood. All raw materials are properly certified.

The production process itself takes place in two vertical retorts and is fully automated. This allows specialists to carefully control chemical indicators - ash content, humidity, content of volatile substances, etc.

Moreover, the process has a closed cycle: organic compounds formed as a result of combustion are disposed of in a special boiler, providing the necessary energy for production. That is, production not only does not pollute the environment, but also provides itself with the necessary energy resource.

This vector of development was chosen not at all for recognition by international experts and not in pursuit of world trends, but with the thought of future generations and the preservation of ecology on a global scale.